Provendor GmbH

Process automation with Make: The path to automated order processing

About our customer Provendor

Provendor GmbH is a full-service procurement service provider with a focus on industrial procurement processes. The company takes on all tasks relating to purchasing and procurement for its customers - with the aim of sustainably reducing effort and costs. Thanks to its technical expertise and experienced specialists, Provendor is active in all material groups and can create targeted added value.

A central component of the business model is the so-called one-vendor principle (one vendor model): As the sole point of contact, Provendor handles the entire procurement process - efficiently, reliably and with personal support. This approach enables lean processes, reduced complexity and fast response times in purchasing.

Key data on the company

- Sector: Industrial procurement services

- Target group: B2B

- Locations: Head office in Germany, Bad Reichenhall, internationally active

- Company size: Medium-sized company with approx. 20 employees

Requirements for the processes

Provendor GmbH wanted to make central business processes more efficient in order to reduce manual activities and establish scalable workflows. The starting point was an unstructured customer request process that needed to be improved.

Initial situation before automation

- Customer inquiries arrived unstructured by email in a central Outlook mailbox.

- They were manually transferred to the weclapp ERP system.

- The internal status was maintained using color coding and labels.

- Article information was often incomplete; many products were missing from the ERP system.

Project objective - Phase 1

The aim of the first project phase was to identify and prioritize digitalization and automation potential in the existing processes as well as the technical implementation with suitable tools. The focus was on

- Reduction of manual work steps

- Development of scalable, digital process structures

- Smooth integration of existing systems

Measures implemented

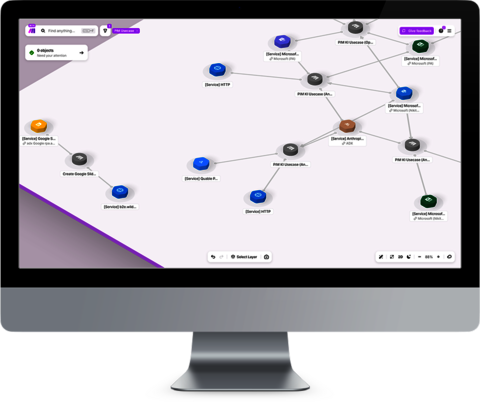

Introduction of the automation platform

- Selection and introduction of Make as a central platform for process automation

- Development of a modular automation scenario

Technical integration

- Connection of weclapp via individual interface

- Integration of the Outlook mailbox via Mail Hook for email forwarding

- Integration of Anthropic Claude for possible AI-supported processing of content

Digitized workflows

- Automated order creation:

- Extraction of relevant information from emails (sender, item names, quantities, item descriptions or links)

- Automatic creation of orders in weclapp

- Faulty emails are moved to a "Check" folder, processed emails are moved to "Done"

- Digitized product research:

- Automated capture and assignment of incomplete or new product information

- Extension to different product types and suppliers

- Orchestration of automated processes:

- Extension of existing scenarios for different email types and senders

- Extension of existing scenarios for different email types and senders

Use in practice

After successful validation in the test phase, the system went live. E-mails in the central mailbox now automatically trigger the creation of orders and quotations in the ERP system - completely digitally and without media disruptions.

Technologies used

- Make - automation platform for linking systems and processes

- Anthropic Claude - AI support for advanced content processing

- Individual development - interface for connecting weclapp

Result: More efficient processes in day-to-day business

By implementing the automation solution, Provendor GmbH benefits from several decisive advantages:

- Significant time savings due to the elimination of manual data entry

- Higher degree of automation ensures more efficient processes and fewer errors

- Future-proof system architecture for easy integration of additional tools and processes

- Introduction of AI technology as the basis for intelligent, scalable process optimization

Customer testimonial

"The collaboration with atlantis dx during the implementation of our automation solution was consistently reliable and efficient. We felt that we received competent advice at all times and now benefit from optimized workflows - which makes our team's daily work noticeably easier."

Stefan Knorsch

Managing Director, Provendor GmbH

Would you also like to start your workflow automation with atlantis dx?

Do you already know exactly what you want to implement or do you still need advice? As a Make Partner, we look forward to hearing from you!